EPS Volume Reduction Machine—Mini MelterRE-E201

Ideal for self-treatment of styrofoam.

Compact and energy-saving type volume reducer.

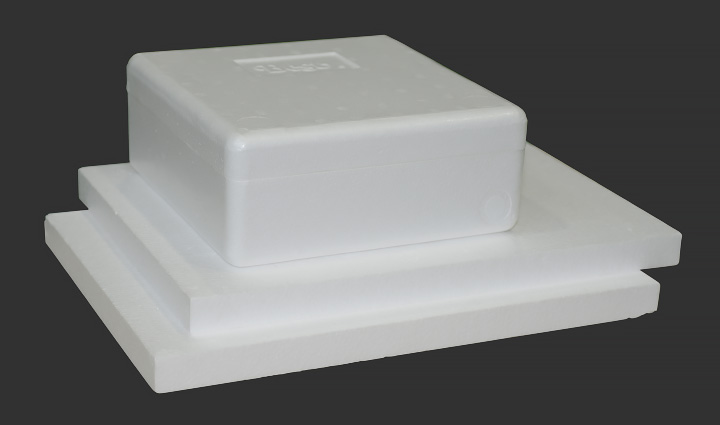

Object to be processed

-

EPS

Expanded

polystyrene -

PSP

Polystyrene

paper -

XPS

Extruded

polystyrene -

EPP

Expanded

polypropylene -

EPE

Expanded

polyethylene

Recycling Process

RE-E201 Product Video

Why Yamamoto?

We're all about making work

safe and comfortable.

While our machines provide unrivalled performance

and create the highest quality ingots,

our real focus is on workplace safety, comfort, and ease of use.

Easy & Simple

Operation

Our machines are designed to be easy for anyone to use. For regular operation, simply touch a button and watch as ingots are automatically formed and cut to the specified size.

Reduces

Work-Related Stress

The warm-up time is only 5 minutes. There is no need to keep the operator waiting before starting operation or resuming after a break. Air cooling is standard, so there is no need to cool the ingot by immersion in water.

Consideration for

the Working Environment

The small heat source makes it difficult for odours to diffuse, and an activated carbon deodoriser is fitted as standard. This promotes a pleasant working environment.

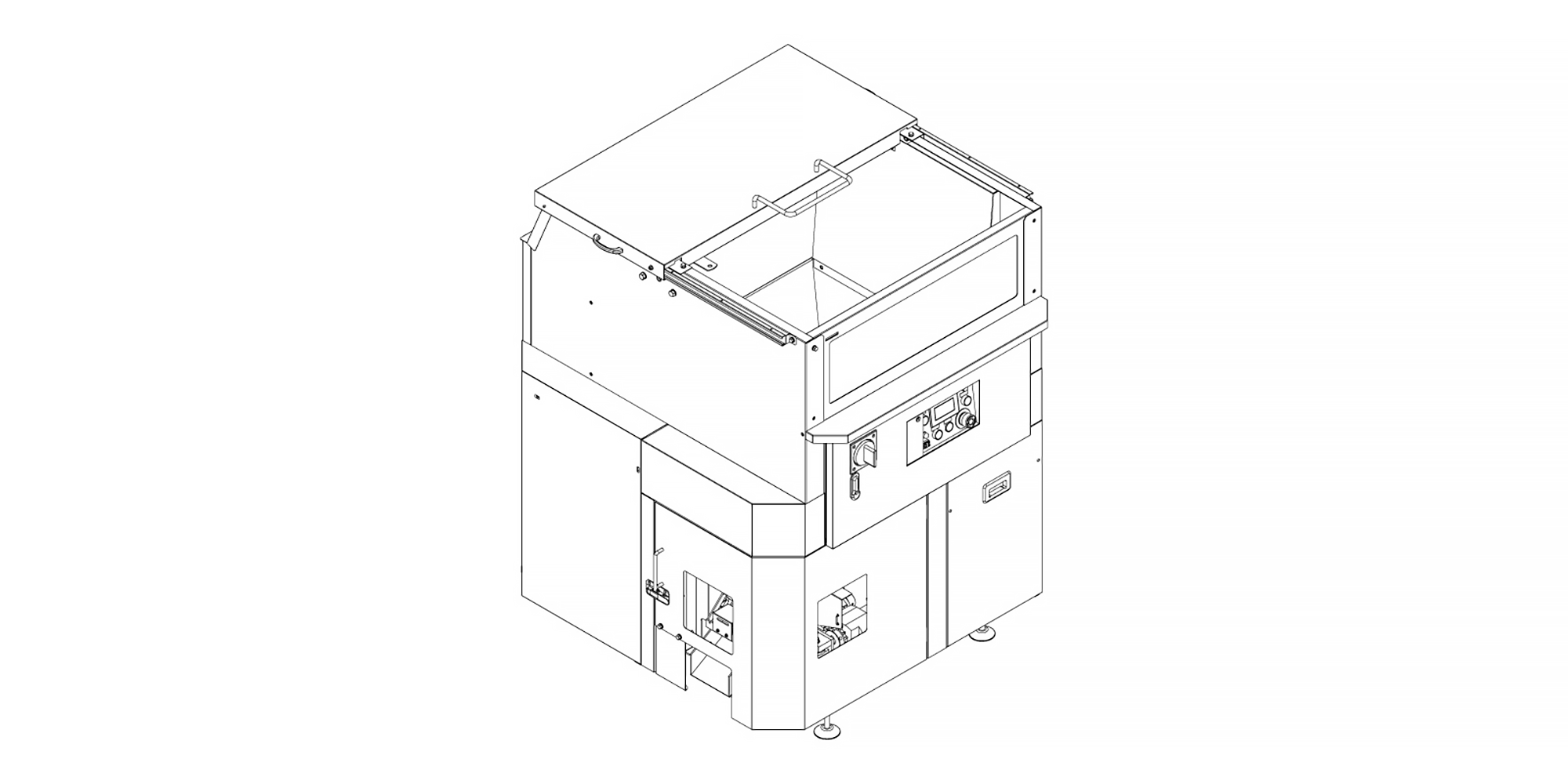

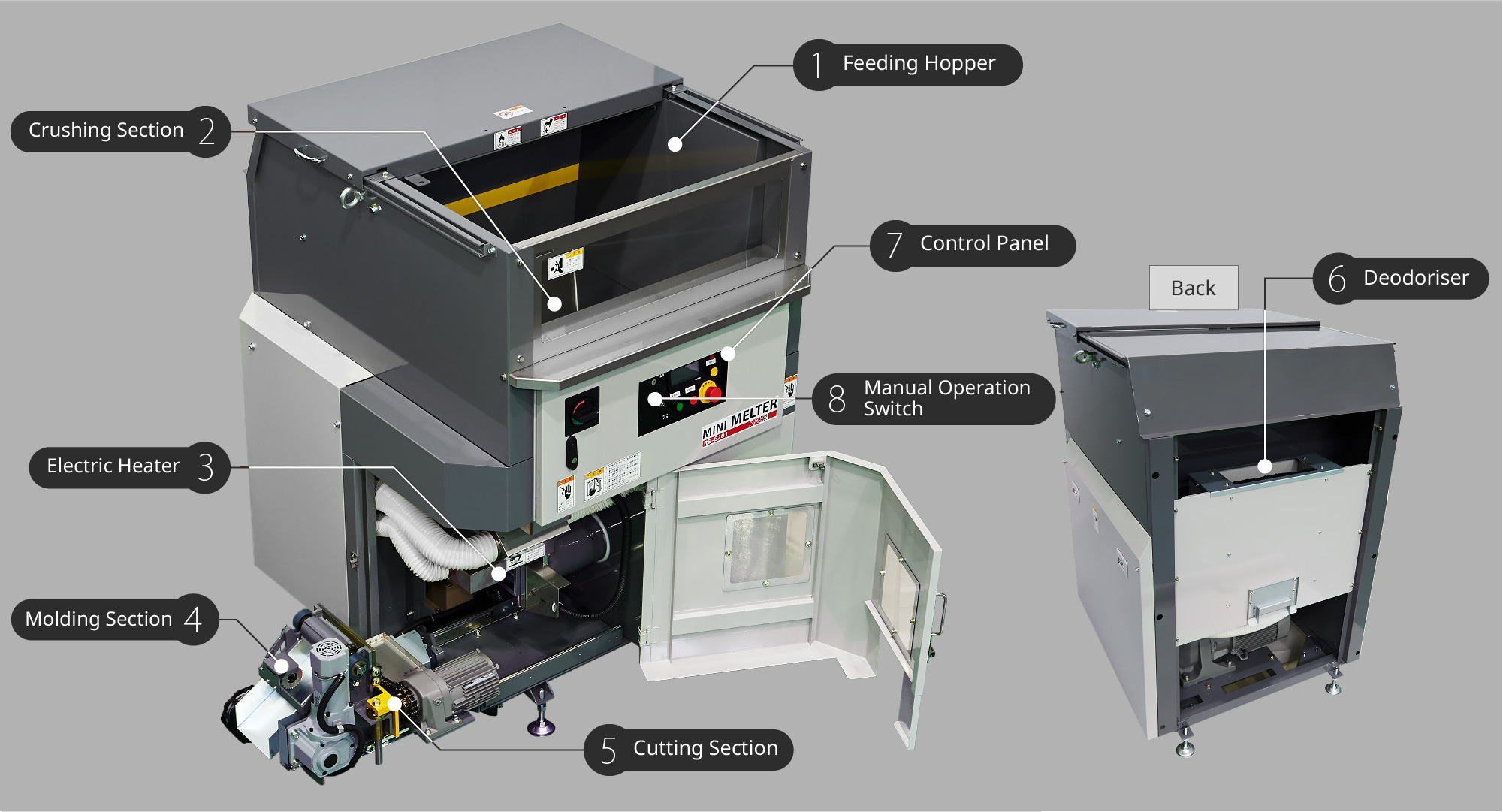

Configuration

The Mini-Melter RE-E201 is

a compact machine with a volume reduction capability of 20 kg per hour.

It is designed for safe and comfortable operation.

Click on a part's name for details.

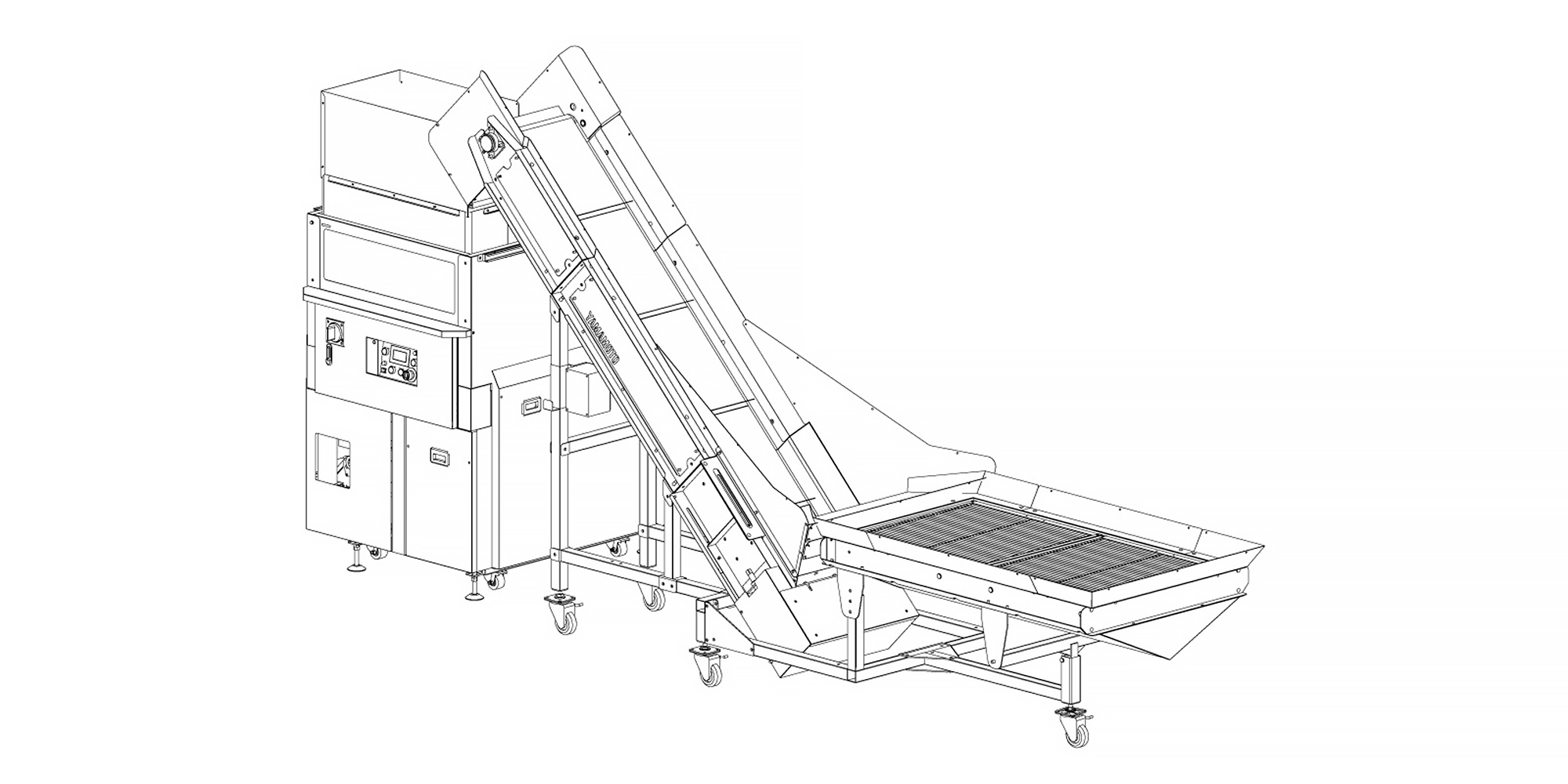

1

Feeding Hopper

The wide hopper is large enough to hold 5–10 fish boxes. The continuous feeding system keeps the work area clean and saves space.

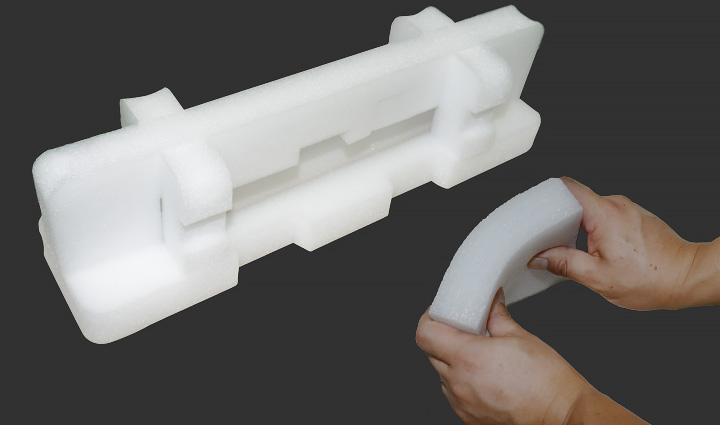

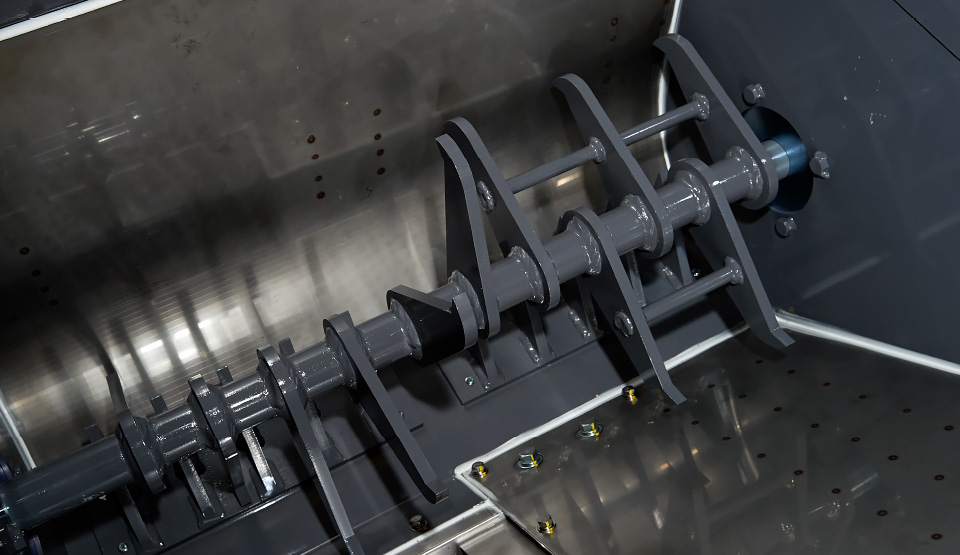

2

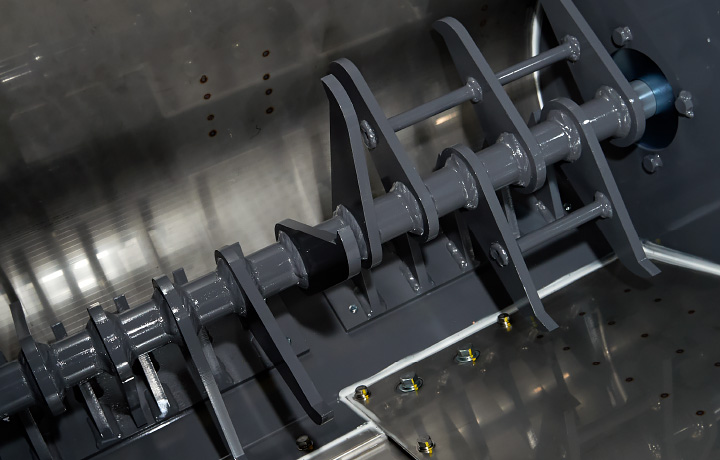

Crushing Section

The crushing blade is our proprietary design and crushes all kinds of styrofoam such as fish boxes, cushioning material, and trays.

3

Electric Heater

Warm-up operation time is only 5 minutes.

Due to the low temperature of 170°C and rapid volume reduction, the ingot is of good quality with little deterioration of physical properties.

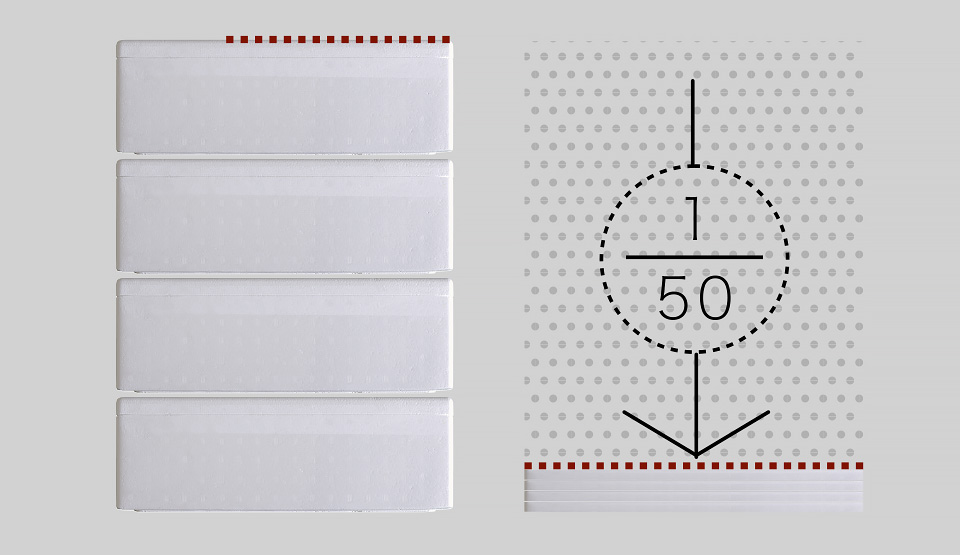

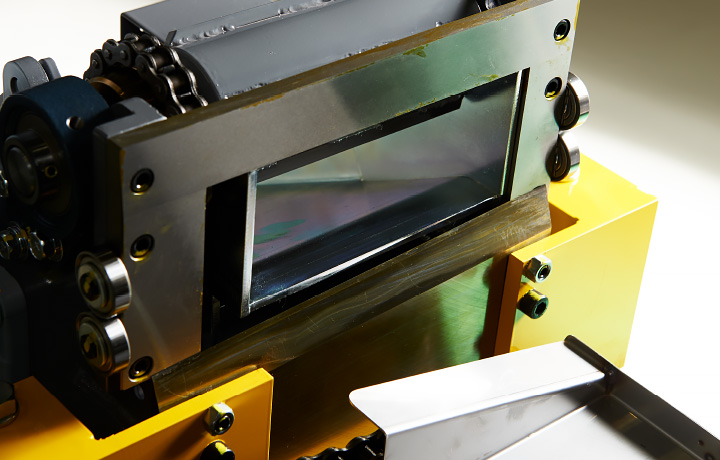

4

Molding Section

The foamed polystyrene melted from the heater is rolled by the forming rolls and formed into the specified shape.

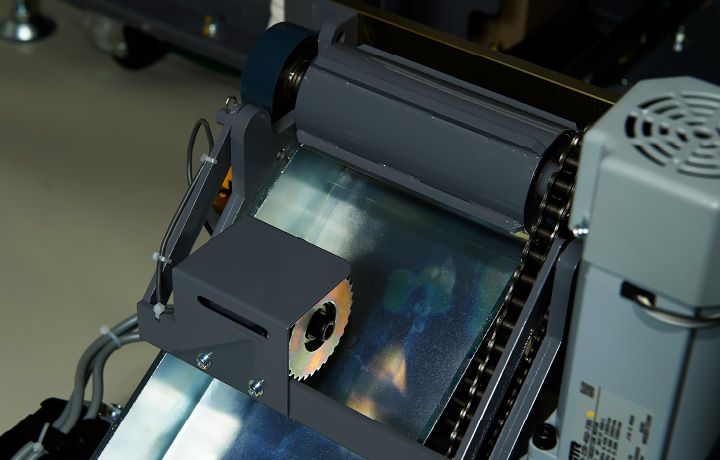

5

Cutting Section

The wheel sensor detects the ingot's discharge, and the cutting blade automatically cuts it to a length of approximately 50 cm.

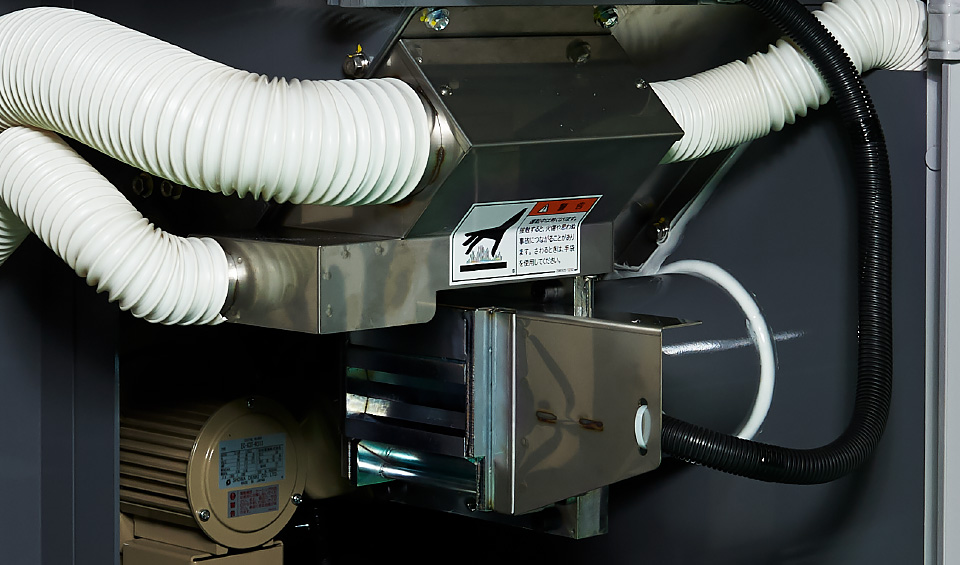

6

Deodoriser

Odour generated during volume reduction is deodorized by activated carbon adsorption system to promote a comfortable working environment. The exhaust air is used for cooling the ingot surface.

7

Control Panel

Precise and meticulous temperature control is possible. In the event of a problem, the alarm indicator light will light up, and a warning sound will be given. At that time, a message will be displayed on the monitor.

8

Manual Operation Switch

A maintenance switch is located inside the panel. By switching to manual operation, the individual motors can be operated separately, e.g. during maintenance.