- Activated Carbon Deodorizer:

Odor generated through bacterial action in the refuse inside the Drum is neutralized by the activated carbon ions, the air is thus deodorized, if not completely, goes along with the refuse when it is discharged to Drum outside.

- Ozone Generator Deodorizer:

To further reinforce the action of activated carbon, ozone is injected into the Drum to kill any residual odor.

- Mist Spray Deodorizer:

When the refuse in the drum is discharged and collected by the RCV, odor neutralizing mist is sprayed over the refuse on the discharge conveyor to catch any odor remained from escaping to the atmosphere.

- Cooling Unit Deodorizer:

Injecting chilled air into the drum, the refuse in the drum is kept cool and delayed decomposition. Accordingly generation of foul odor is suppressed.

- Load cell:

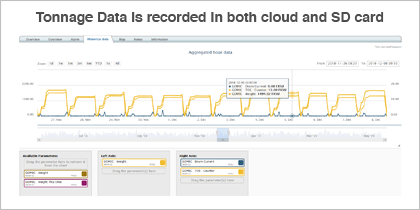

Weighting the refuse stored inside the drum. By connecting with recording equipment, time series data can be obtained.

- Manual inlet:

To accommodate wider ranges of usages, refuse inlet arrangement can be arranged flexibly. Both space saving and safety feature can be achieved by highly designed manual type inlet gate.

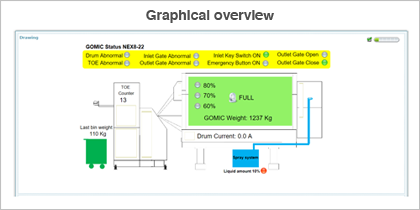

- Smart monitoring system:

Push alert is sent to users when the drum becomes full or any malfunction occurs and other events are detected. Condition of machine and refuse loading can be also monitored at real time basis via mobile or client computer devises.

Hygienic Garbage Stock SystemMade in Japan

Hygienic Garbage Stock SystemMade in Japan

- HOME

- Options